Filtralite® Pure denitrification biofilter at Formiche Alto (SP)

The process of denitrification in the field of drinking water treatment is a big challenge. Contamination of aquifers by nitrates, due to the excess of fertilization in agriculture, is a recurrent problem throughout the world and especially in regions with important agricultural development, like Mediterranean Europe.

Biological denitrification is a very reliable and performant solution for drinking water treatment

Biological denitrification involves the biological oxidation of organic substrates in water treatment using nitrate or nitrite as the electron acceptor instead of oxygen. In a Drinking Water Treatment Plant, denitrification is carried out in just one step inside an anaerobic bio-filter filled with the filter media Filtralite® Pure which is the optimum carrier for the denitrification biofilm. The system is simple to design, very reliable, highly performant and with low operational cost.

Designing a denitrification biofilter with Filtralite® Pure

Ingeobras has designed and built in Formiche Alto (Teruel Province - Spain) in 2017 a denitrification biofilter with Filtralite® Pure as the biofilm carrier. The DWTP treats groundwater with good quality, except for the nitrates content which is around 60 ppm (content variable depending on the season).

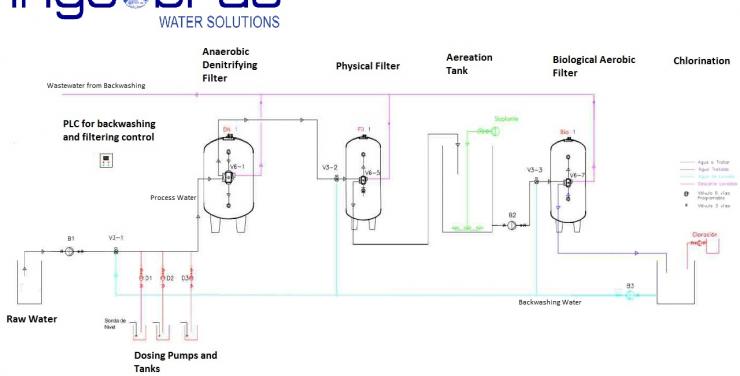

A small drinking water treatment scheme (5 m3/h) was built in four steps: (1) Denitrification Bio-Filter Anaerobic to remove nitrates, (2) Physical Filtration to remove Suspended Solids (3) Biological Aerated Filter to remove remaining organic matter (4) Disinfection with Chlorine.

The DWTP of Formiche Alto has been designed to operate with a removal performance of 60% to get a final NO3 value in the outlet water below 25 ppm. The quantity of backwash water needed is between the 5-10% of the total filtered water produced.

The plant has an automatic operation which reduces the operational costs. It’s estimated by Ingeobras that for a DWTP designed to treat NO3 (60 ppm/l) with a daily flow of 1000 m3, the total operation cost is around 0.16 €/m3 with the following cost breakdown:

- 0.08 €/m3 for reagents (mainly organic matter),

- 0.04 €/m3 for energy

- and 0,04 €/m3 for maintenance.

The filter media Filtralite® Pure, which is the heart of the system, has a lifespan over 20 years.

The project’s CAPEX to build up the DWTP is, in comparison with other solutions (reverse osmosis, electro dialysis, distillation or chemical reduction), substantially lower because of the simplicity of the technology used. Biological denitrification in DWTP removes between 70–95 % of nitrates: the most efficient of all technologies. Removal obtained with ion exchange, chemical reduction, electro dialysis and reverse osmosis were 80– 90 %, 33–90 %, 30–50 % and 50–96 %, respectively.

Denitrification solution in a water drinking plant using Filtralite® Pure in a biological filter is an excellent option, in terms of water quality, CAPEX and OPEX. The process is very robust and reliable with a strong component of economic and environmental sustainability.